Serck is known worldwide for cooling expertise, from massive industrial infrastructure, through to precision high-performance coolers. Our racing services division offers the following services to the performance motorsport industry, as well as aerospace and other precision applications.

All tests are available as part of a service cleanse package, and units are returned with a comprehensive test report data sheet.

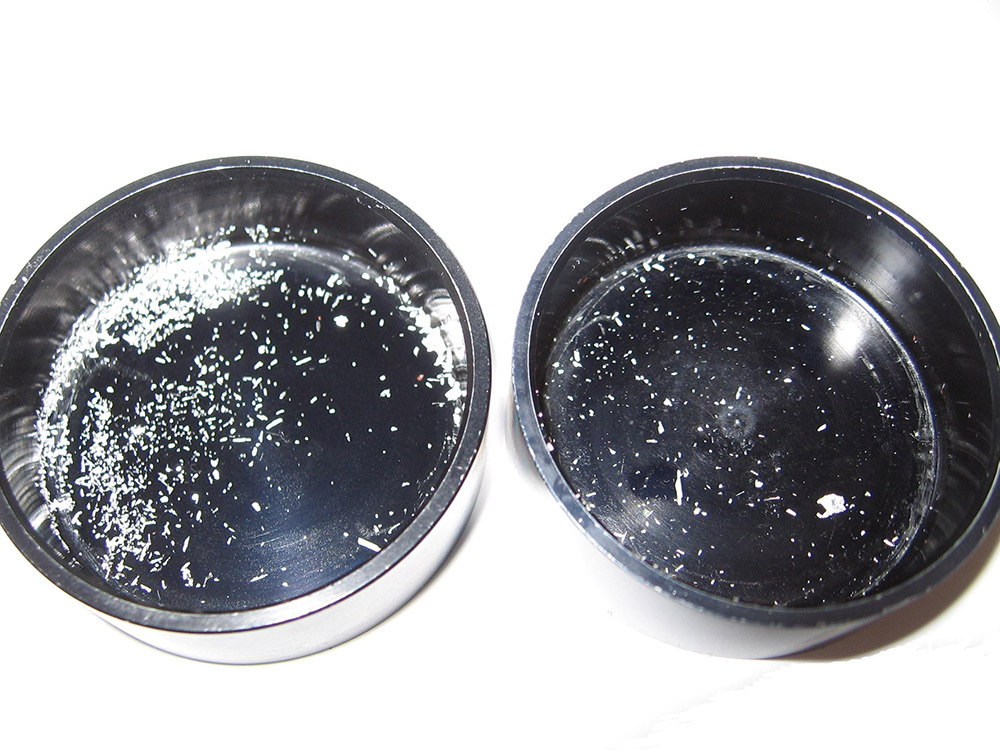

Micron Analysis Testing

Specifically designed for Formula One and working closely with F1 engine manufacturers, micron analysis testing is paramount when re-using coolers for each race or test, maintaining performance and eliminating the threat of component failure.

As part of a service cleanse, photo analysis is carried out to assess and reduce levels of particulate contamination. Our service is dedicated to cleanliness and quality, and by using the latest techniques in fluid dynamics, service flow rigs, turbulation concepts, and micron analysis testing we can identify particulate levels to 1 micron, without using harmful pulse techniques that will cause fatigue.

Our micron analysis testing service is suitable as part of a regular maintenance schedule for oil coolers, hydraulic coolers, charge air coolers and ERS coolers from manufacture and race used units.

High Pressure Testing

Suitable for Formula One and many other areas in motorsport, aerospace and automotive, our pressure testing is part of our service cleanse package and is very effective at sustained high pressures as we can test up to 20bar. We use Helium Grade A as leaks are easily detected should any be present even the smallest pin holes are clearly evident via this process.

Our testing setup features a wier system that allows for visibility throughout the process, and our entire system is fitted with filtered water systems as well as internal tank lighting for 100% clarity while testing. All tests are carried for 15 minute minimum periods on both sides of the heat exchanger, allowing for an extensive and effective visual test.

Flow Testing

Flow testing allows us to provide performance data for any given cooler type and core configuration. We can flow up to 3.1 litres per second, and typically provide 5 flow rates from the maximum flow to a minimum. From these 5 flow rates we record the pressure drop at each point and present this with the unit in hard copy or electronically.

Flow Testing is becoming increasingly popular for high-performance and historic cooler owners, especially as part of our service cleaning package as we record the history of an active heat exchanger throughout its working life. This allows us to monitor any changes in the performance of the unit as it progresses through time.

In preparation for a flow test, the unit will require a flush through to eliminate any contamination of the flow rig. If the unit is oil related, an additional flushing process is required to remove all oil and contaminant deposits prior to flow testing. Flow testing is then done with deionised water at 55 degrees.